When it comes to adding designs to t-shirts or other items, two popular methods stand out: DTF Transfers and Screen Printing. Both methods offer unique ways of incorporating cool pictures or words onto materials, but they differ significantly in their approach. Let’s simplify these two methods to understand what sets them apart.

What is DTF Transfer?

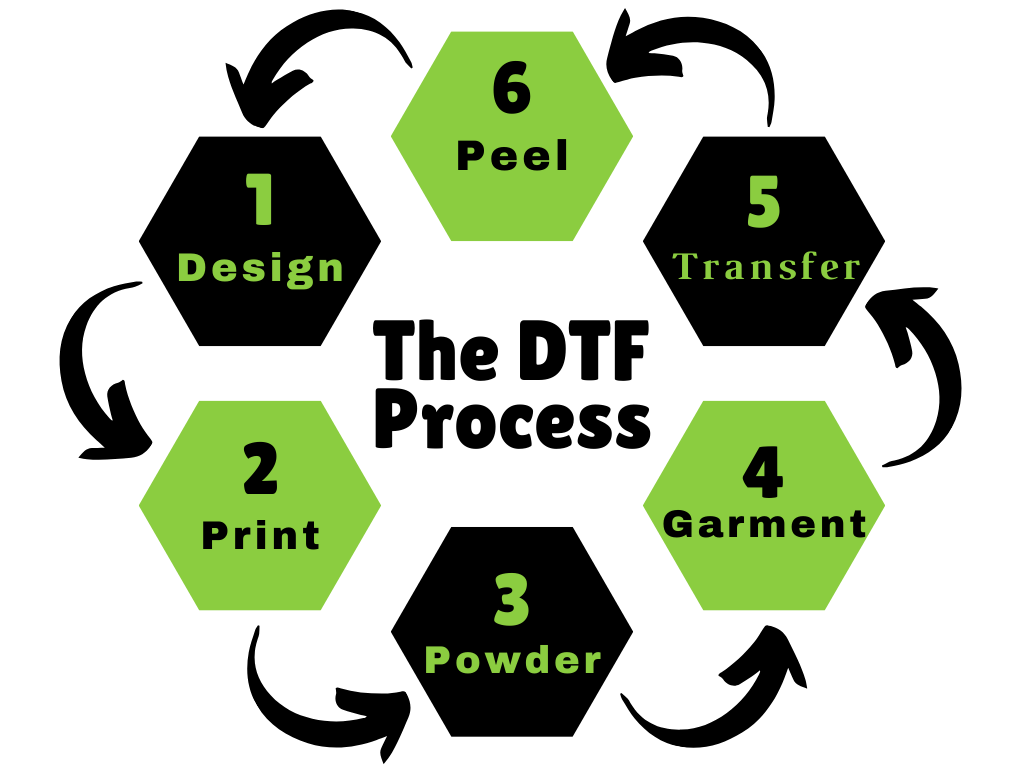

DTF, which stands for Direct to Film, involves printing a design onto a special film and then transferring that design onto fabric. It’s akin to printing a picture from a computer onto paper, except the image goes onto a shirt. Here’s the process:

- Printing the Design: A machine prints your design onto a clear film.

- Adding Glue Powder: After printing, a special glue powder is applied over the design.

- Transferring to Fabric: The design, now coated with glue, is heated and pressed onto the fabric, akin to applying a sticker.

What is Screen Printing?

Screen Printing is a traditional method of adding designs to fabric using a stencil (or template) to apply layers of ink onto the printing surface, one color at a time. This method requires manual labor and is ideal for large batches of shirts. Here’s how it works:

- Creating the Stencil: A design is carved out on a mesh screen.

- Applying the Ink: Ink is spread over the stencil, pushing it through the mesh onto the fabric.

- Drying: The ink dries, leaving the design on the fabric.

The Differences

- Technology: DTF is a newer, digital technology, allowing for detailed and colorful designs with less manual labor. Screen Printing is more manual and traditional, requiring physical stencils and screens.

- Materials: DTF can be used on a variety of fabrics, whereas Screen Printing might have limitations based on ink and fabric compatibility.

Which One to Choose?

Deciding between DTF Transfers and Screen Printing may seem daunting, but if you’re looking for versatility, precision, and efficiency, especially for both small and large orders, DTF Transfers shine brightly.

- Versatility and Precision: DTF stands out with its ability to print highly detailed and colorful designs, adapting effortlessly to various fabric types.

- Efficiency on All Scales: Advances in technology mean DTF can handle large quantities efficiently, making it a competitive option for orders of any size.

- Ease of Use: DTF simplifies the production process, reducing preparation time significantly.

- Quality and Durability: DTF prints not only look great but are also durable, withstanding washing and wear.

Given these advantages, DTF Transfers offer a compelling choice for anyone looking to produce high-quality printed materials, whether you’re a small business, an artist, or even a large enterprise. The efficiency, quality, and flexibility of DTF make it an outstanding option for bringing your creative visions to life, regardless of the order size.